What is Kaizen?

Kaizen is a Japanese business philosophy that focuses on continuous improvement. The word “Kaizen” itself means “change for the better” or “continuous improvement” in Japanese. It is a concept that is deeply ingrained in Japanese culture and has been widely adopted by businesses around the world.

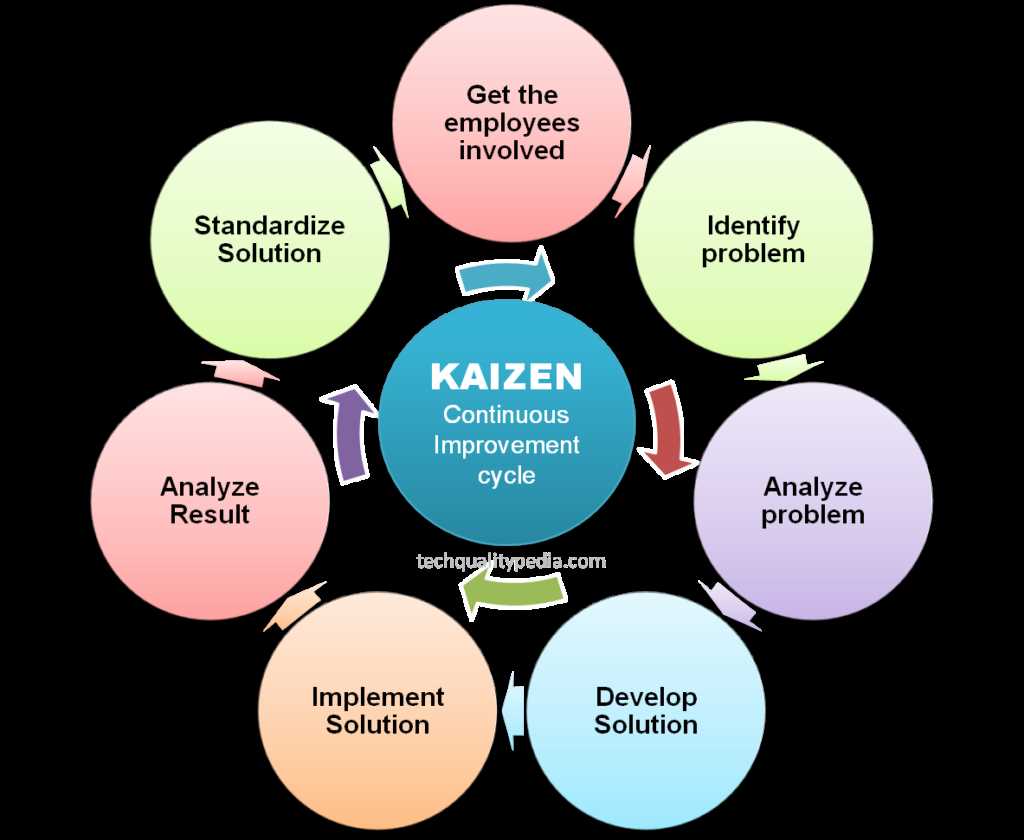

At its core, Kaizen is about making small, incremental changes to improve processes, products, and services. It emphasizes the importance of involving all employees in the improvement process and encourages them to constantly seek ways to make things better.

One of the key principles of Kaizen is the belief that even the smallest improvements can have a significant impact over time. By continuously making small improvements, businesses can achieve greater efficiency, quality, and customer satisfaction.

Kaizen is not a one-time event or a quick fix. It is a long-term commitment to continuous improvement. It requires a shift in mindset and a culture of collaboration, innovation, and learning. Kaizen encourages employees to identify problems, suggest solutions, and implement changes on a daily basis.

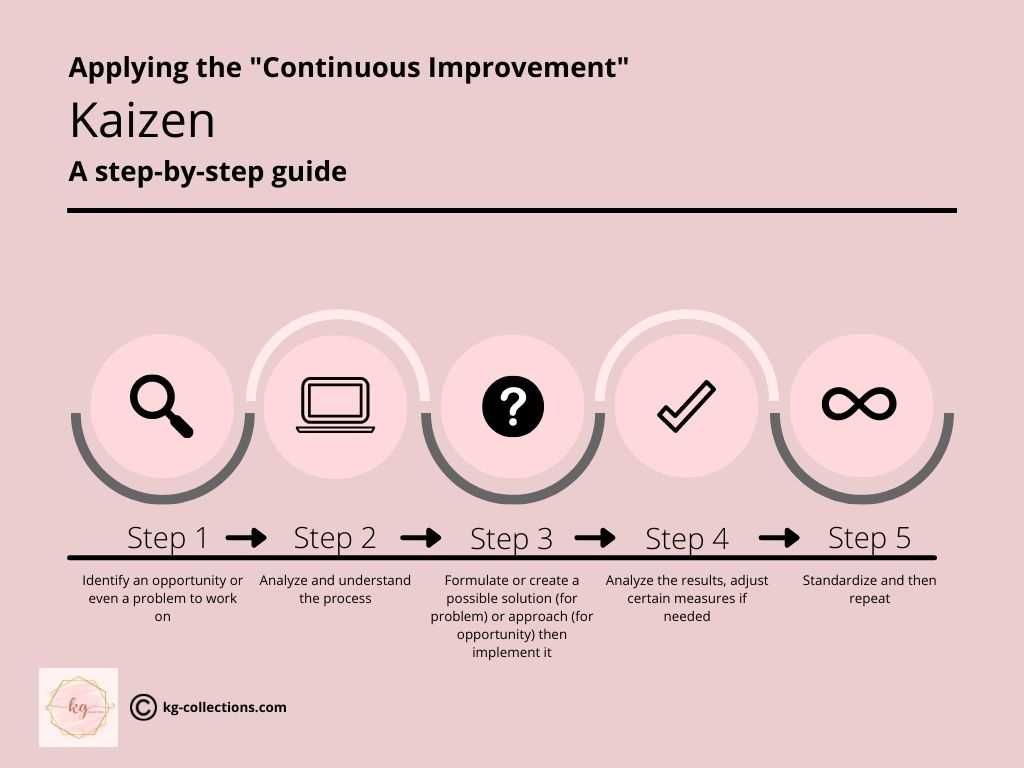

There are several key concepts and practices associated with Kaizen, including:

- Gemba: This refers to the practice of going to the place where the work is done to observe and understand the current state of affairs.

- PDCA Cycle: This stands for Plan, Do, Check, Act, and is a problem-solving method that involves continuous experimentation and learning.

- Standardization: This involves creating and following standardized processes to ensure consistency and eliminate waste.

- 5S: This is a workplace organization method that focuses on Sort, Set in Order, Shine, Standardize, and Sustain.

Overall, Kaizen is a powerful philosophy that can help businesses of all sizes and industries improve their operations, increase productivity, and stay competitive in an ever-changing market. It is a mindset that encourages continuous learning, innovation, and growth.

At the core of the Japanese business philosophy is the concept of Kaizen, which means “continuous improvement” in Japanese. This concept emphasizes the importance of constantly striving to improve processes, products, and services in order to meet the changing needs and expectations of customers. It is a mindset that encourages employees at all levels of the organization to identify problems, suggest solutions, and work together to implement improvements.

One of the key principles of Kaizen is teamwork. In Japanese businesses, there is a strong emphasis on collaboration and cooperation among employees. This is reflected in the way work is organized, with teams often being responsible for specific tasks or projects. By working together, employees can share their knowledge and expertise, learn from each other, and find innovative solutions to problems.

In summary, the Japanese business philosophy is a unique approach to business management that emphasizes continuous improvement, teamwork, and a focus on customer satisfaction. It is a mindset that encourages employees to constantly strive for excellence, work together to find innovative solutions, and deliver high-quality products and services. By adopting this philosophy, businesses can improve their efficiency, competitiveness, and overall success.

The Origins of Kaizen

Kaizen, the Japanese business philosophy, has its origins in Japan’s post-World War II economic recovery. After the war, Japan was faced with a devastated economy and a need for rapid reconstruction. The country’s industries were in shambles, and there was a desperate need for improvement.

One of the key figures in the development of Kaizen was Taiichi Ohno, an engineer at Toyota. Ohno believed that the key to improving productivity and quality was to eliminate waste and inefficiency in all aspects of the production process. He developed a system of production called the Toyota Production System, which became the foundation for Kaizen.

The Toyota Production System emphasized the importance of teamwork, problem-solving, and employee involvement. It introduced the concept of “Just-in-Time” production, which aimed to produce goods and services exactly when they were needed, eliminating the need for excess inventory.

Another important figure in the development of Kaizen was Masaaki Imai, who popularized the concept in his book “Kaizen: The Key to Japan’s Competitive Success.” Imai emphasized the importance of small, incremental improvements in all areas of the business, from production to customer service.

Over time, Kaizen spread beyond the manufacturing sector and became a widely adopted philosophy in Japanese business culture. It became ingrained in the way Japanese companies operated, with a focus on continuous improvement and the pursuit of excellence.

Today, Kaizen is recognized as a powerful tool for improving productivity, quality, and customer satisfaction. It has been adopted by companies around the world and is considered a key component of lean management and Six Sigma methodologies.

A Brief History of the Japanese Business Philosophy

One of the key figures in the development of Kaizen was Dr. W. Edwards Deming, an American statistician and management consultant. In the 1950s, Deming introduced his ideas on quality management to Japanese business leaders. His teachings emphasized the importance of continuous improvement, teamwork, and employee involvement in the production process.

The Japanese embraced Deming’s ideas and incorporated them into their own business practices. They saw the potential of Kaizen to transform their companies and make them more efficient and competitive. Japanese businesses began implementing Kaizen principles in all aspects of their operations, from manufacturing to customer service.

Over time, Kaizen became deeply ingrained in Japanese culture and society. It became not just a business philosophy but also a way of life. The Japanese people embraced the idea of constant improvement in all areas of their lives, including work, education, and personal development.

As a result of their commitment to Kaizen, Japanese companies achieved remarkable success. They became known for their high-quality products, efficient production processes, and exceptional customer service. Japanese businesses, such as Toyota, Sony, and Honda, became global leaders in their respective industries.

Today, Kaizen continues to be a fundamental principle in Japanese business culture. It is a philosophy that encourages companies to constantly strive for improvement, no matter how small. Japanese businesses understand that even the smallest changes can have a significant impact on their overall performance and success.

The Principles of Kaizen

Kaizen is based on several key principles that guide its implementation and success in Japanese businesses. These principles include:

1. Continuous Improvement:

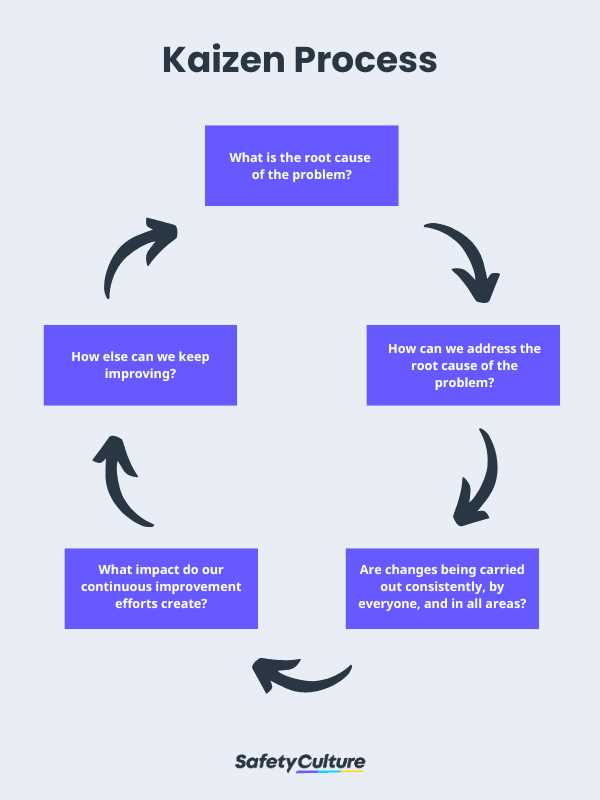

Kaizen emphasizes the importance of continuous improvement in all aspects of a business. It encourages employees at all levels to constantly look for ways to improve processes, systems, and products. This mindset of continuous improvement helps businesses stay competitive and adapt to changing market conditions.

2. Employee Involvement:

Kaizen recognizes that employees are the key to driving improvement. It encourages employee involvement and empowerment by giving them the authority and responsibility to identify and implement improvements. This not only increases employee engagement but also taps into their knowledge and expertise to drive meaningful change.

3. Waste Reduction:

Kaizen focuses on identifying and eliminating waste in all its forms. This includes reducing unnecessary steps in processes, eliminating defects, minimizing waiting times, and optimizing resource utilization. By reducing waste, businesses can improve efficiency, reduce costs, and enhance overall productivity.

4. Standardization:

Kaizen promotes the establishment of standardized processes and procedures. Standardization ensures consistency and reliability in operations, making it easier to identify and address problems. It also provides a baseline for continuous improvement efforts and enables businesses to measure progress and track results.

5. Quality First:

Kaizen places a strong emphasis on quality. It encourages businesses to prioritize quality in all aspects of their operations, from product design and manufacturing to customer service. By focusing on quality, businesses can build a reputation for excellence and customer satisfaction, leading to increased loyalty and market share.

6. Problem Solving:

Kaizen encourages a proactive problem-solving approach. It emphasizes the importance of identifying and addressing problems at their root cause, rather than just treating the symptoms. This involves using tools and techniques such as root cause analysis, brainstorming, and the Plan-Do-Check-Act (PDCA) cycle to systematically solve problems and prevent their recurrence.

7. Continuous Learning:

Kaizen promotes a culture of continuous learning and development. It encourages employees to acquire new skills, knowledge, and expertise to enhance their performance and contribute to the overall improvement of the business. This includes providing training opportunities, promoting knowledge sharing, and fostering a supportive learning environment.

By embracing these principles, businesses can create a culture of continuous improvement and innovation, leading to long-term success and sustainable growth.

Key Concepts and Practices of the Japanese Business Philosophy

The Japanese business philosophy of Kaizen is built on several key concepts and practices that are essential for its successful implementation. These concepts and practices are deeply ingrained in Japanese culture and have contributed to the country’s economic success.

1. Continuous Improvement: Kaizen emphasizes the importance of continuous improvement in all aspects of business operations. This means constantly seeking ways to make processes more efficient, reduce waste, and improve quality. It involves a mindset of always striving for better and never being satisfied with the status quo.

2. Employee Involvement: Kaizen recognizes that employees are the key to driving improvement. It encourages active participation and involvement from all levels of the organization, from top management to frontline workers. Employees are empowered to identify problems, propose solutions, and implement changes. This creates a culture of ownership and accountability.

3. Gemba Walks: Gemba is a Japanese term that means “the actual place.” In the context of Kaizen, it refers to going to the actual place where work is done to observe and understand the current state of operations. Gemba walks involve managers and supervisors visiting the shop floor or work areas to directly observe processes, identify inefficiencies, and engage with employees. This hands-on approach helps to identify improvement opportunities and build relationships with employees.

4. Standardization: Kaizen emphasizes the importance of standardizing processes and procedures. Standardization ensures consistency and enables continuous improvement by providing a baseline for comparison. It helps to identify variations and deviations from the standard, which can then be addressed and improved upon.

6. Just-in-Time (JIT) Production: JIT is a production strategy that aims to minimize inventory and eliminate waste. It involves producing and delivering products or services just in time to meet customer demand. JIT requires close coordination and collaboration across the entire supply chain. It helps to reduce lead times, improve efficiency, and increase customer satisfaction.

7. Total Quality Management (TQM): TQM is a holistic approach to quality management that is closely aligned with Kaizen. It involves a commitment to continuous improvement, customer focus, and employee involvement. TQM aims to achieve excellence in all aspects of business operations and deliver superior products and services to customers.

These key concepts and practices of the Japanese business philosophy of Kaizen have been widely adopted by organizations around the world. They provide a framework for continuous improvement and help to create a culture of excellence and innovation.

Emily Bibb simplifies finance through bestselling books and articles, bridging complex concepts for everyday understanding. Engaging audiences via social media, she shares insights for financial success. Active in seminars and philanthropy, Bibb aims to create a more financially informed society, driven by her passion for empowering others.