Make-or-Buy Decision: Factors to Consider

When making a make-or-buy decision, there are several factors that businesses need to consider. These factors can help determine whether it is more beneficial to produce a product or service in-house or to outsource it to a third-party vendor. Here are some key factors to consider:

1. Cost:

One of the primary factors to consider is the cost associated with both options. This includes not only the direct costs of production or outsourcing, but also the indirect costs such as training, infrastructure, and maintenance. It is important to conduct a thorough cost analysis to determine which option is more cost-effective in the long run.

2. Expertise and Resources:

Another factor to consider is the level of expertise and resources required for the product or service. If the business lacks the necessary skills or resources in-house, outsourcing may be the better option. On the other hand, if the business has a competitive advantage in terms of expertise or resources, it may be more beneficial to keep the production in-house.

3. Quality Control:

Quality control is another important factor to consider. If the business has strict quality requirements and wants to maintain full control over the production process, keeping it in-house may be the better option. However, if the third-party vendor has a proven track record of delivering high-quality products or services, outsourcing may be a viable option.

4. Flexibility and Scalability:

The ability to quickly adapt to changing market conditions and scale production is another factor to consider. If the business anticipates fluctuations in demand or the need for rapid scalability, outsourcing may provide more flexibility. However, if the business requires tight control over production and wants to have the ability to make quick changes, keeping it in-house may be more suitable.

5. Risk Management:

Risk management is an important consideration when making a make-or-buy decision. Outsourcing may introduce additional risks such as dependency on the third-party vendor, potential breaches of confidentiality, or delays in delivery. On the other hand, keeping production in-house may carry risks such as increased costs, lack of expertise, or potential capacity constraints. It is crucial to assess and mitigate these risks before making a decision.

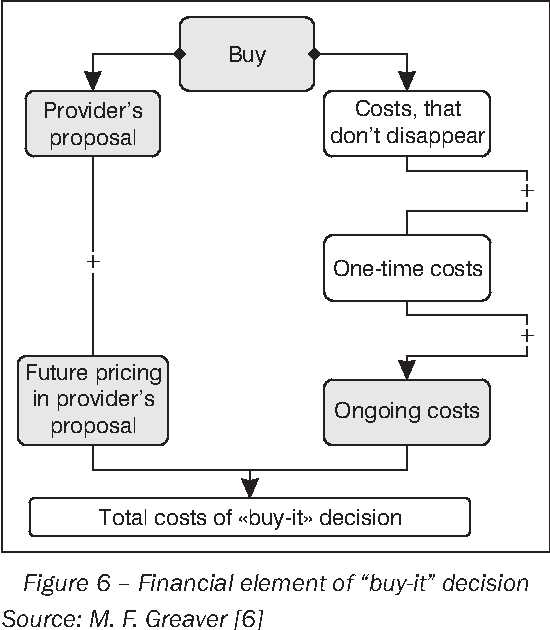

Cost Analysis and Financial Considerations

When making a make-or-buy decision, one of the most important factors to consider is the cost analysis and financial implications. This analysis involves comparing the costs associated with producing a product or providing a service in-house versus outsourcing it to a third-party vendor.

1. Direct Costs

The first step in the cost analysis is to identify and calculate the direct costs involved in both options. Direct costs are those that can be directly attributed to the production or provision of the product or service. These costs typically include raw materials, labor, equipment, and overhead expenses.

2. Indirect Costs

In addition to direct costs, it is important to consider the indirect costs associated with both options. Indirect costs are those that are not directly tied to the production or provision of the product or service but still impact the overall cost. These costs may include administrative expenses, training costs, maintenance costs, and other overhead expenses.

3. Economies of Scale

Another factor to consider is the potential economies of scale that can be achieved through outsourcing. By outsourcing, companies can take advantage of the vendor’s expertise and resources, which may result in cost savings due to economies of scale. For example, a third-party vendor may be able to negotiate better deals with suppliers or have access to specialized equipment that can reduce costs.

4. Quality and Reliability

While cost is an important consideration, it is equally important to assess the quality and reliability of the outsourced product or service. Lower costs may not always translate to better quality, and it is essential to ensure that the vendor can meet the company’s standards and requirements. This may involve conducting thorough research, checking references, and even visiting the vendor’s facilities.

5. Risk Assessment

When considering the financial implications of outsourcing, it is crucial to assess the risks involved. Outsourcing may introduce certain risks, such as potential delays, communication issues, or loss of control over the production process. These risks should be carefully evaluated and compared to the potential cost savings before making a decision.

| Cost Analysis | In-House | Outsourcing |

|---|---|---|

| Direct Costs | Calculate the direct costs of producing the product or providing the service in-house. | Calculate the direct costs of outsourcing the production or service to a third-party vendor. |

| Indirect Costs | Consider the indirect costs associated with in-house production or service provision. | Consider the indirect costs associated with outsourcing, such as administrative expenses and training costs. |

| Economies of Scale | Assess the potential cost savings that can be achieved through economies of scale. | Consider the potential cost savings that can be achieved by leveraging the vendor’s expertise and resources. |

| Quality and Reliability | Evaluate the quality and reliability of in-house production or service provision. | Assess the quality and reliability of the outsourced product or service. |

| Risk Assessment | Consider the risks associated with in-house production or service provision. | Assess the risks involved in outsourcing and compare them to the potential cost savings. |

Strategic Considerations and Long-Term Benefits

When making a make-or-buy decision, it is important to consider the strategic implications and long-term benefits of outsourcing. While cost savings are often a primary motivator for outsourcing, there are other factors to consider that can have a significant impact on the overall success of the decision.

One strategic consideration is the ability to focus on core competencies. Outsourcing non-core activities allows a company to concentrate its resources and expertise on areas that directly contribute to its competitive advantage. By delegating certain tasks to external vendors, companies can free up internal resources and improve their overall efficiency.

Additionally, outsourcing can provide access to specialized skills and knowledge that may not be available in-house. This can be particularly beneficial for complex or technical tasks that require specific expertise. By partnering with external vendors who have the necessary skills and experience, companies can enhance their capabilities and deliver higher quality products or services.

Furthermore, outsourcing can help companies expand their global reach and enter new markets. By partnering with vendors who have a presence in different regions, companies can leverage their local knowledge and networks to gain a competitive advantage. This can be especially valuable for companies looking to expand internationally or enter emerging markets.

Another long-term benefit of outsourcing is the potential for innovation and collaboration. By working with external vendors, companies can tap into new ideas, perspectives, and technologies. This can lead to innovation and the development of new products or services. Additionally, outsourcing can foster collaboration between different organizations, creating opportunities for knowledge sharing and joint problem-solving.

Finally, outsourcing can provide flexibility and scalability. As business needs change, companies can easily adjust their outsourcing arrangements to meet new demands. This allows companies to scale their operations up or down without incurring significant costs or disruptions to their core business.

Emily Bibb simplifies finance through bestselling books and articles, bridging complex concepts for everyday understanding. Engaging audiences via social media, she shares insights for financial success. Active in seminars and philanthropy, Bibb aims to create a more financially informed society, driven by her passion for empowering others.