What is Lean Six Sigma?

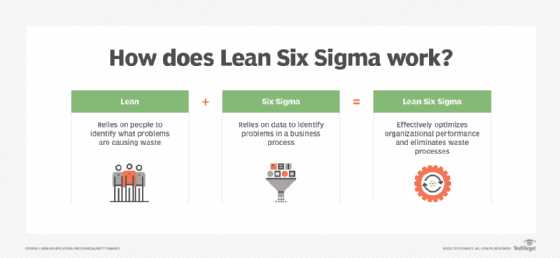

Lean Six Sigma is a methodology that combines the principles of Lean Manufacturing and Six Sigma to improve business processes and eliminate waste. It focuses on reducing variation and defects in order to increase efficiency and customer satisfaction.

Lean Manufacturing

Lean Manufacturing is a philosophy that originated from the Toyota Production System. It aims to eliminate waste and create value by focusing on continuous improvement, respect for people, and the elimination of non-value-added activities. The key principles of Lean Manufacturing include:

- Identifying and eliminating waste

- Creating a smooth and efficient flow of work

- Empowering employees to make improvements

- Using visual management tools to track progress

Six Sigma

Six Sigma is a data-driven methodology that focuses on reducing variation and defects in processes. It aims to achieve near-perfect quality by using statistical analysis to identify and eliminate the root causes of defects. The key principles of Six Sigma include:

- Defining the problem and setting clear goals

- Measuring the current performance and collecting data

- Analyzing the data to identify the root causes of defects

- Improving the process by implementing solutions

- Controlling the process to sustain the improvements

By combining the principles of Lean Manufacturing and Six Sigma, Lean Six Sigma provides a comprehensive approach to process improvement. It helps organizations reduce waste, improve quality, and increase customer satisfaction. By eliminating non-value-added activities and reducing defects, Lean Six Sigma enables organizations to operate more efficiently and effectively.

Definition, Principles, and Benefits of Lean Six Sigma

Lean Six Sigma is a methodology that combines the principles of Lean Manufacturing and Six Sigma to improve processes, reduce waste, and increase efficiency in organizations. It focuses on eliminating defects, reducing variation, and improving customer satisfaction.

Definition

Lean Six Sigma is a data-driven approach that aims to identify and eliminate waste, defects, and errors in processes. It combines the concepts of Lean Manufacturing, which focuses on reducing waste and improving flow, with Six Sigma, which aims to reduce variation and defects.

The goal of Lean Six Sigma is to improve the quality and efficiency of processes by identifying and eliminating non-value-added activities, reducing cycle times, and improving customer satisfaction. It involves a systematic approach to problem-solving, data analysis, and process improvement.

Principles

There are several key principles that guide Lean Six Sigma:

- Customer Focus: Lean Six Sigma aims to understand and meet the needs of the customer by delivering products and services that meet their expectations.

- Data-Driven Decision Making: Lean Six Sigma relies on data and statistical analysis to make informed decisions and drive process improvements.

- Process Improvement: Lean Six Sigma focuses on identifying and eliminating waste, defects, and errors in processes to improve efficiency and effectiveness.

- Employee Involvement: Lean Six Sigma encourages the involvement and empowerment of employees at all levels of the organization to drive process improvements.

Benefits

Implementing Lean Six Sigma can bring numerous benefits to organizations, including:

- Improved Quality: By reducing defects and errors, Lean Six Sigma improves the quality of products and services, leading to increased customer satisfaction.

- Increased Efficiency: Lean Six Sigma identifies and eliminates waste, streamlines processes, and reduces cycle times, resulting in increased efficiency and productivity.

- Cost Savings: By reducing waste and improving efficiency, Lean Six Sigma can lead to significant cost savings for organizations.

- Improved Customer Satisfaction: Lean Six Sigma focuses on meeting customer needs and expectations, leading to improved customer satisfaction and loyalty.

- Employee Engagement: Lean Six Sigma encourages employee involvement and empowerment, leading to increased engagement and motivation.

Lean Six Sigma Principles

Lean Six Sigma is a methodology that combines the principles of Lean Manufacturing and Six Sigma to improve business processes and eliminate waste. The following are the key principles of Lean Six Sigma:

| Principle | Description |

| 1. Customer Focus | Lean Six Sigma aims to understand and meet the needs of customers by delivering products and services that provide value. |

| 2. Process Improvement | The methodology focuses on continuously improving processes to increase efficiency, reduce defects, and eliminate waste. |

| 3. Data-Driven Decision Making | Lean Six Sigma relies on data analysis to make informed decisions and drive improvements. |

| 4. Teamwork and Collaboration | The methodology encourages cross-functional collaboration and teamwork to achieve common goals and solve problems. |

| 5. Continuous Learning and Development | Lean Six Sigma promotes a culture of continuous learning and development to foster innovation and improvement. |

| 6. Leadership Engagement | Leadership plays a crucial role in driving Lean Six Sigma initiatives, providing support, and creating a culture of improvement. |

These principles form the foundation of Lean Six Sigma and guide organizations in their journey towards process excellence and operational efficiency. By embracing these principles, businesses can streamline their operations, reduce costs, enhance customer satisfaction, and gain a competitive edge in the market.

Key Elements for Success in Lean Six Sigma

Implementing Lean Six Sigma can bring significant benefits to an organization, but it requires careful planning and execution. There are several key elements that contribute to the success of Lean Six Sigma initiatives:

1. Leadership Commitment

Leadership commitment is crucial for the successful implementation of Lean Six Sigma. Top management should actively support and champion the initiative, providing the necessary resources and creating a culture of continuous improvement. Without strong leadership commitment, it is difficult to sustain the momentum and overcome resistance to change.

2. Clearly Defined Goals and Objectives

Setting clear and measurable goals is essential for guiding the Lean Six Sigma initiative. These goals should align with the organization’s strategic objectives and be communicated to all employees. Clear goals help focus efforts and provide a sense of direction, motivating employees to actively participate in the improvement process.

3. Employee Engagement and Training

Engaging employees at all levels of the organization is crucial for the success of Lean Six Sigma. Employees should be encouraged to participate in improvement projects and given the necessary training to understand and apply Lean Six Sigma tools and methodologies. Training programs should be tailored to the specific needs of each employee, ensuring they have the skills and knowledge to contribute effectively to the initiative.

4. Data-Driven Decision Making

Lean Six Sigma relies on data and facts to drive decision making. Organizations should establish robust data collection and analysis processes to identify areas for improvement and measure the impact of implemented changes. Data should be collected consistently and accurately, and analyzed using statistical tools to identify root causes and validate improvement efforts.

5. Continuous Improvement Culture

A culture of continuous improvement is a fundamental element of Lean Six Sigma. Organizations should foster an environment where employees are encouraged to identify and address problems, suggest improvements, and share best practices. Continuous improvement should be embedded in the organization’s values and supported by performance metrics and recognition systems.

6. Effective Project Management

Effective project management is essential for the successful execution of Lean Six Sigma projects. Organizations should establish clear project charters, define roles and responsibilities, and provide the necessary support and resources. Project teams should follow a structured methodology, such as DMAIC (Define, Measure, Analyze, Improve, Control), to ensure consistent and effective problem-solving.

By focusing on these key elements, organizations can increase the likelihood of success in their Lean Six Sigma initiatives. Implementing Lean Six Sigma requires a commitment to continuous improvement and a systematic approach to problem-solving, but the benefits can be substantial, including improved quality, increased efficiency, and enhanced customer satisfaction.

Benefits of Lean Six Sigma

Implementing Lean Six Sigma methodologies in your organization can bring a wide range of benefits. Here are some of the key advantages:

1. Improved Efficiency

Lean Six Sigma focuses on eliminating waste and reducing variation in processes. By streamlining operations and eliminating non-value-added activities, organizations can achieve significant improvements in efficiency. This leads to shorter lead times, reduced costs, and increased productivity.

2. Enhanced Quality

One of the main goals of Lean Six Sigma is to deliver products and services that meet or exceed customer expectations. By identifying and eliminating defects and errors, organizations can improve the quality of their products and services. This leads to higher customer satisfaction, increased customer loyalty, and a better reputation in the market.

3. Cost Reduction

Lean Six Sigma helps organizations identify and eliminate activities that do not add value to the customer. By reducing waste, organizations can significantly reduce costs. This includes reducing inventory, minimizing rework and scrap, and optimizing resource utilization. The cost savings achieved through Lean Six Sigma can have a direct impact on the bottom line.

4. Increased Customer Satisfaction

By focusing on delivering high-quality products and services that meet customer requirements, organizations can greatly improve customer satisfaction. Lean Six Sigma helps organizations understand customer needs and expectations, and align their processes to meet those needs. This leads to increased customer loyalty, repeat business, and positive word-of-mouth recommendations.

5. Employee Engagement

Implementing Lean Six Sigma encourages employee involvement and empowerment. By involving employees in process improvement initiatives, organizations can tap into their knowledge and expertise. This not only leads to better solutions and ideas, but also increases employee satisfaction and engagement. Employees feel valued and motivated when they can contribute to the success of the organization.

6. Competitive Advantage

Organizations that successfully implement Lean Six Sigma gain a competitive advantage in the market. By improving efficiency, quality, and customer satisfaction, they can differentiate themselves from competitors. This allows organizations to attract more customers, increase market share, and ultimately achieve long-term success.

Emily Bibb simplifies finance through bestselling books and articles, bridging complex concepts for everyday understanding. Engaging audiences via social media, she shares insights for financial success. Active in seminars and philanthropy, Bibb aims to create a more financially informed society, driven by her passion for empowering others.