What is Acceptable Quality Level (AQL) and How It Works?

Acceptable Quality Level (AQL) is a statistical measurement used in quality control to determine the maximum number of defective units that are considered acceptable in a given sample size. It is commonly used in manufacturing and production industries to ensure that products meet the required quality standards before they are released to the market.

Definition of Acceptable Quality Level (AQL)

The AQL is typically expressed as a ratio or percentage. For example, an AQL of 2.5% means that no more than 2.5% of the products in a sample can be defective for it to be considered acceptable. This means that if a sample size of 100 units is inspected, no more than 2.5 units can be defective.

How Acceptable Quality Level (AQL) Works

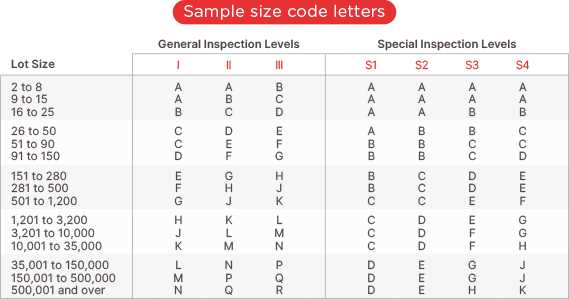

When implementing AQL, a random sample of products is selected from a batch or lot for inspection. The sample size is determined based on statistical calculations to ensure a representative sample. The products in the sample are then inspected for defects according to predefined criteria.

If the number of defective units in the sample exceeds the AQL, the entire batch or lot is considered to be non-compliant and may be rejected or subject to further inspection. On the other hand, if the number of defective units falls within the AQL, the batch or lot is considered to be compliant and can proceed to the next stage of production or be released to the market.

The AQL is an important tool in quality control as it helps to ensure that products meet the required quality standards and minimize the risk of defective products reaching the customers. It provides a clear benchmark for manufacturers and customers to evaluate the quality of products and make informed decisions.

Definition of Acceptable Quality Level (AQL)

The Acceptable Quality Level (AQL) is a statistical measurement used in quality control to determine the maximum number of defective units that are considered acceptable in a particular batch or lot of products. It is commonly used in manufacturing and production industries to ensure that the products meet the required quality standards.

AQL is expressed as a percentage or a ratio and represents the maximum allowable number of defects or non-conforming units in a sample size. It is used to determine whether a batch of products should be accepted or rejected based on the number of defects found in the sample.

How AQL Works

When conducting quality control inspections, a sample size is randomly selected from a batch of products. The sample is then inspected for defects or non-conforming units based on predetermined criteria. The number of defects found in the sample is compared to the AQL to determine whether the batch should be accepted or rejected.

For example, if the AQL for a particular product is set at 2.5%, it means that up to 2.5% of the units in the sample can be defective or non-conforming without the batch being rejected. If the number of defects found in the sample exceeds the AQL, the batch is considered to have failed the quality control inspection and may be rejected or subject to further investigation.

By using AQL, manufacturers can ensure that their products meet the required quality standards while also balancing the costs and resources associated with quality control inspections. It provides a standardized method for evaluating the quality of a batch of products and helps to minimize the risk of delivering defective or non-conforming units to the customer.

How Acceptable Quality Level (AQL) Works

The Acceptable Quality Level (AQL) is a statistical measurement used in quality control to determine the maximum number of defective units that can be considered acceptable in a given production batch. It is widely used in industries such as manufacturing, pharmaceuticals, and electronics to ensure that products meet the required quality standards.

1. Defining the AQL

The first step in applying the AQL is to define the acceptable quality level for a particular product or process. This involves determining the maximum number of defects or non-conforming units that can be tolerated without compromising the overall quality. The AQL is usually expressed as a percentage or a number of defects per hundred units.

2. Sampling Plan

Once the AQL is defined, a sampling plan is developed to assess the quality of the production batch. This involves randomly selecting a sample of units from the batch and inspecting them for defects. The size of the sample and the criteria for accepting or rejecting the batch are determined based on statistical calculations.

3. Inspection and Decision Making

During the inspection process, the selected sample units are thoroughly examined for defects according to the specified criteria. The defects can be categorized as major, minor, or critical, depending on their impact on the product’s functionality or safety. The number of defects found in the sample is compared to the acceptance criteria defined by the AQL.

If the number of defects in the sample is within the acceptable range defined by the AQL, the entire production batch is considered acceptable. However, if the number of defects exceeds the AQL, the batch is rejected, and appropriate corrective actions are taken to address the quality issues.

4. Continuous Improvement

The AQL is not a fixed value and can be adjusted based on the desired level of quality and the specific requirements of the product or process. It is important for organizations to regularly review and update their AQL to ensure that it remains relevant and effective in maintaining the desired quality standards.

By implementing the AQL and continuously monitoring the quality of their products, organizations can identify areas for improvement and take proactive measures to enhance their overall quality control processes. This leads to increased customer satisfaction, reduced costs, and improved competitiveness in the market.

Emily Bibb simplifies finance through bestselling books and articles, bridging complex concepts for everyday understanding. Engaging audiences via social media, she shares insights for financial success. Active in seminars and philanthropy, Bibb aims to create a more financially informed society, driven by her passion for empowering others.